Blogs

PCB Fundamentals: Advantages and Disadvantages of Single and Multilayer PCBs

||

Before designing a printed circuit board, you need to determine whether you want to use a single-layer or multilayer pcb fabrication.Both design types are common. So which type is right for your project? What's the difference? As the name suggests, single-layer boards have only one layer of substrate, also called a baseboard, while multilayer PCBs have multiple layers.

Advantages of single layer boards and their applications

Single-layer boards, sometimes called monolayers, PCB factory usually have components on one side of the board and copper wires on the other, and consist of a base layer, a conductive metal layer, a protective solder mask, and screen printing.

1) The advantages and disadvantages of single-layer PCBs are as follows.

Advantages:

Lower cost cost design and production is simpler delivery time can be shorter

Disadvantages:

For complex projects, especially when the number of components, size requirements, single board can not deal with the ability to handle smaller, larger sizes and greater weight

(2) single layer PCB applications

Single-panel because of the low cost and relatively easy to produce, become the first choice for a variety of electronic products. Although multilayer boards are becoming more popular as electronics become more complex, single-layer boards are still widely used. They are usually found in single-function devices that do not need to store large amounts of data or access networks.

Single-layer printed circuit boards are commonly used in small household appliances, such as coffee makers. They are also PCBs used in most calculators, radios, printers and LED lights. Simpler storage devices such as solid state drives also commonly use single-sided PCBs, such as power supplies and many different types of sensor assemblies.

Advantages of Multilayer PCBs and Applications

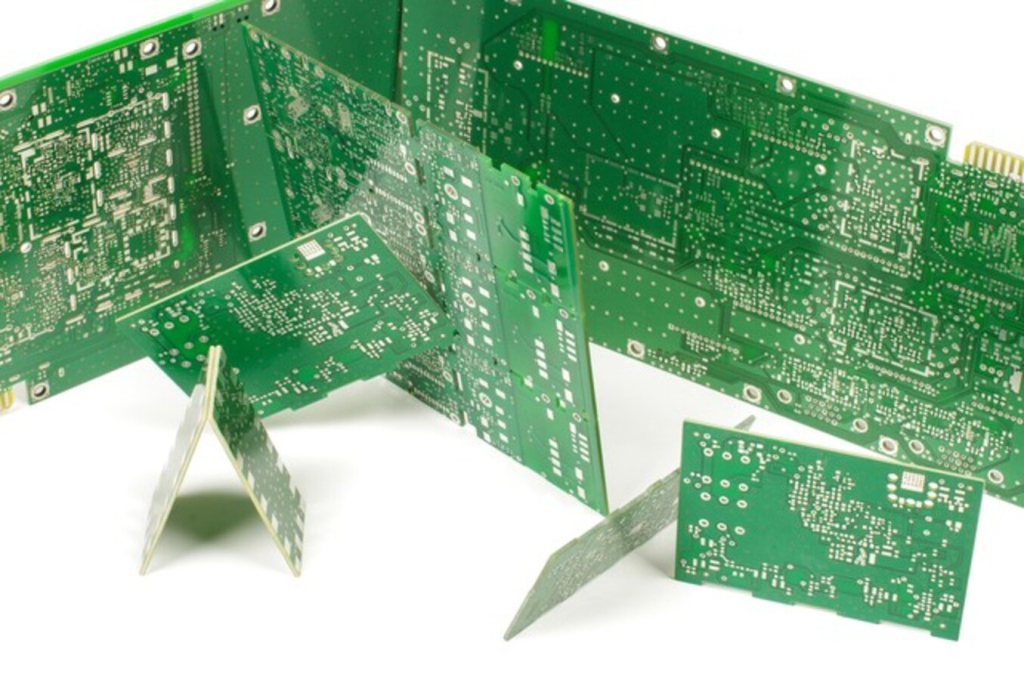

Multilayer PCBs consist of a stack of three or more double-sided boards. Usually multilayer boards typically have an even number of layers, ranging from 4 to 12. Why not use an odd number of layers? Because an odd number of layers can lead to problems such as warping and twisting after soldering.

Each substrate layer on a multilayer board has a conductive metal on both sides. The boards are joined together using a number of specialized adhesives and we have different insulating construction materials present between each board. At the outermost edge of the multilayer board is the solder resist layer.

The said multilayer uses through holes to allow the different layers to communicate with each other. There are three general types of perforations:

Through-hole: Through each layer of the board.

Blind holes: connecting the outer layer to the inner layer

Buried holes:Connects two inner layers so they are not visible from the outside.

1) The advantages and disadvantages of multilayer PCBs are analyzed below:

Pros:

Ability to handle more complex functions with higher quality Greater power, greater processing power and faster speed Enhanced durability Smaller size and lighter weight

Disadvantages:

Higher cost, more complex design and production, longer lead times and more complex maintenance.

2) Multilayer PCB Applications

With the development of technology, multilayer printed circuit boards are becoming increasingly popular. Many of today's electronic devices are complex in function and small in size, making it necessary to use multilayer structures on their circuit boards.

Multilayer printed circuit boards are found in many computer components, including motherboards and servers. From laptops and tablets to smartphones and smartwatches. Smartphones usually require about 12 layers. Other products that aren't as complex as smartphones, but are too complicated for single-sided printed circuit boards, typically use four to eight layers. Examples include microwave ovens and air conditioners.

In addition companies due to the reliability, small size and lightweight design required for the development of our medical technology equipment, they can also usually pass between them to run on boards with more than three layers. Multilayer printed circuit boards are also used in X-ray machines, heart monitors, CAT scanning system equipment and many other aspects of student applications.

The automotive and aerospace industries are also increasingly using durable and lightweight electronic components, often using multilayer panels as well. These components must be able to withstand wear and tear, high temperatures and other harsh conditions. On-board computers, GPS systems, engine sensors, and headlight switches are also typically multilayer boards.

How to Determine Whether You Need a Single-Layer or Multi-Layer PCB

To determine whether your project requires a single or multi-layer printed circuit board, consider the requirements of the project and the most appropriate type. Ask yourself the following five questions.

1. What level of functionality do I need? If it is more complex, you may need multilayer.

2. What are the maximum different size requirements for the board? Multi-layer boards can accommodate students with more social functions in a smaller space.

Durability first? If so, use multilayer.

4. What is my budget? For more modest budgets, single-layer boards work best.

5. How long do I need a PCB? Single-layer PCBs have shorter transfer times than multilayer PCBs.

Allother author's recent blogs

- • Multi-purpose applications: 6 multi-purpose stamps recommended in 2024!

- • Understand the standards for pesticide residues in food

- • What is the difference between a kol and an internet celebrity?

- • Marketing is the science and art of how companies discover

- • Entry Level Best New Vintage Wine Tudor Ranger Ranger Watch